“Treatment Trains” Combine Remediation Technologies for More Effective Environmental Cleanup

The silver bullet, the one stop shop, the fix-all cure-all. We have all heard the promises for each new remediation technology. However, after a few years, the paint dulls, and we realize, again, that the newest technology has limitations and does not work for all contaminants in all media, in all geology.

The good news is that there are now dozens of technologies and products that we can use and combine to manage, reduce and control risks from environmental contamination. This is known as a “treatment train.”

A treatment train is a plan to use the most effective aspects of multiple technologies and/or products in a manner that overcomes the limitations of each.

A Sample Treatment Train: LUST facility

The following example of a treatment train would be a beneficial plan to address a Non-Aqueous Phase Liquid (NAPL) gasoline/diesel release from a leaking underground storage tank (LUST) facility.

Car #1: DPE System

Shortly after the release, the NAPL is mobile and relatively easy to recover from the soils/groundwater using a dual phase extraction (DPE) system.

Benefits: The benefits of a DPE system include plume encapsulation, large initial contaminant mass reduction rates, and treatment of both soils and groundwater.

Limitations: The imitations of a DPE system include decreased recovery rates / recovery efficiency over time and spatial limitations for recovery wells.

Car #2: NAPL surfactant flush

After the DPE system reaches asymptotic recovery rates, a NAPL surfactant flush can mobilize sorbed contaminants that have a greater affinity for soils than groundwater.

Benefits: The benefits of a NAPL surfactant include mobilization/transmissivity of sorbed* NAPL contaminants, increased recoverability of NAPL contaminants, removal of NAPL as a source to continued/future groundwater contamination and relatively lower cost.

Limitations: The limitations of a NAPL surfactant include need for a containment/recovery system; need of a network of application points (injection wells), and it does not reduce concentrations of dissolved phase contaminants.

Car #3: Sulfate Enhanced Biodegradation

After the first two treatment train cars addressed the NAPL as a continued source for groundwater contamination, there is still a need to reduce dissolved groundwater contamination. Sulfate enhanced biodegradation is the process of adding dissolved sulfate to groundwater as an alternative electron acceptor (i.e. oxygen alternative) for the naturally occurring bacteria that biodegrade dissolved petroleum compounds.

Benefits: The benefits of sulfate enhanced biodegradation include low effort technology, low cost of sulfate source (less than $1.00 per pound), ability to use previously installed injection well/application network, and final dissolved concentrations often less than laboratory method detection limits (MDLs).

Limitations: The limitations of sulfate enhanced biodegradation include a need for a network of application points, does not work well with mobile NAPL and does not address soil contamination.

Car #4: Engineering and Institutional Controls

Engineering and institutional controls are physical and legal instruments used to control or restrict actions that could result in unacceptable exposure to environmental contaminants. Examples of controls are restrictive covenants (RCs) to prevent use of groundwater, keep pavement/surface cover in place, and limit property use (i.e. industrial only with no residential use).

Benefits: Restricts activities that could result in unacceptable exposure. Reduces exposure risk. Allows cleanup goals to be greater than Garden of Eden clean. Facilitates quicker path to closure. Allows future brownfield redevelopment of property.

Limitations: Does not remove or reduce contamination. Regulators often require active remediation (cars one through three) prior to implementing. Difficult to implement on off-site properties.

Historically, the use of any one of the technologies listed above by itself was proposed as an all-encompassing solution that would reduce contamination such that LUST closure could be achieved.

However, limitations for each technology has, over time, demonstrated that none alone would be sufficient to control risks from the example environmental contamination resultant from a gasoline/diesel LUST release. By designing a corrective action plan (CAP) that incorporates multiple technologies, the resulting CAP will be greater than the sum of the individual parts because various components may be re-used and/or compliment the other components.

The Full Picture – a Conceptual Site Model (CSM)

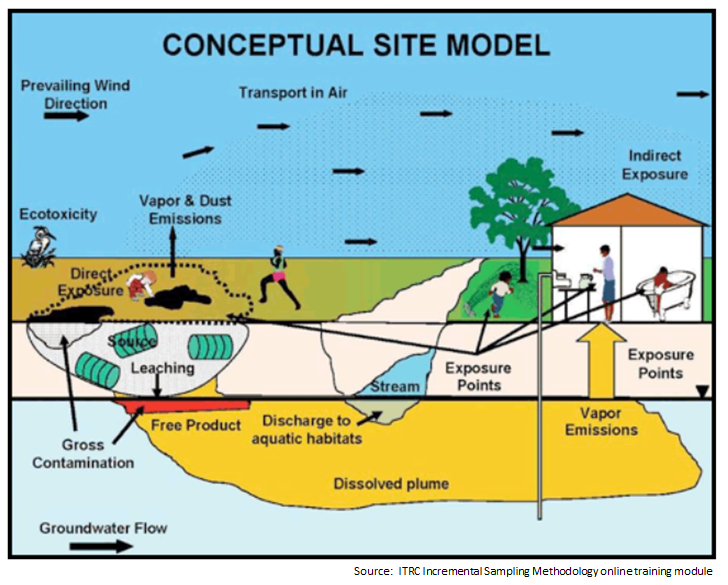

Treatment trains can be “assembled” for most any kind of environmental contamination as long as one has a complete understanding of the contamination and affected media, which is often compiled in a conceptual site model (CSM). The CSM is essential for choosing the appropriate cars to include in treatment trains.

Treatment trains can be “assembled” for most any kind of environmental contamination as long as one has a complete understanding of the contamination and affected media, which is often compiled in a conceptual site model (CSM). The CSM is essential for choosing the appropriate cars to include in treatment trains.

The first car should generally be a technology that will address the contaminant source and reduce large scale impact of contamination. The second car is generally a technology that is complementary to the first car in a manner that increases efficiency or addresses first car limitations. The third car generally finishes the job and allows the owner/manager to reach the defined goal for contaminant management, reduction and/or control.

While certain types of environmental contamination (e.g. gas station LUST release) may have a commonality that allows them to start with a certain treatment train framework, one should realize that each site should have a train that is designed/assembled specifically for the site conditions defined in the CSM.

Mastering the tools is only half of the battle, knowing how to use each of them in the right combination is the key to a successful clean up.

* A physical and chemical process by which one substance becomes attached to another

Publication Details

Date

October 3, 2017