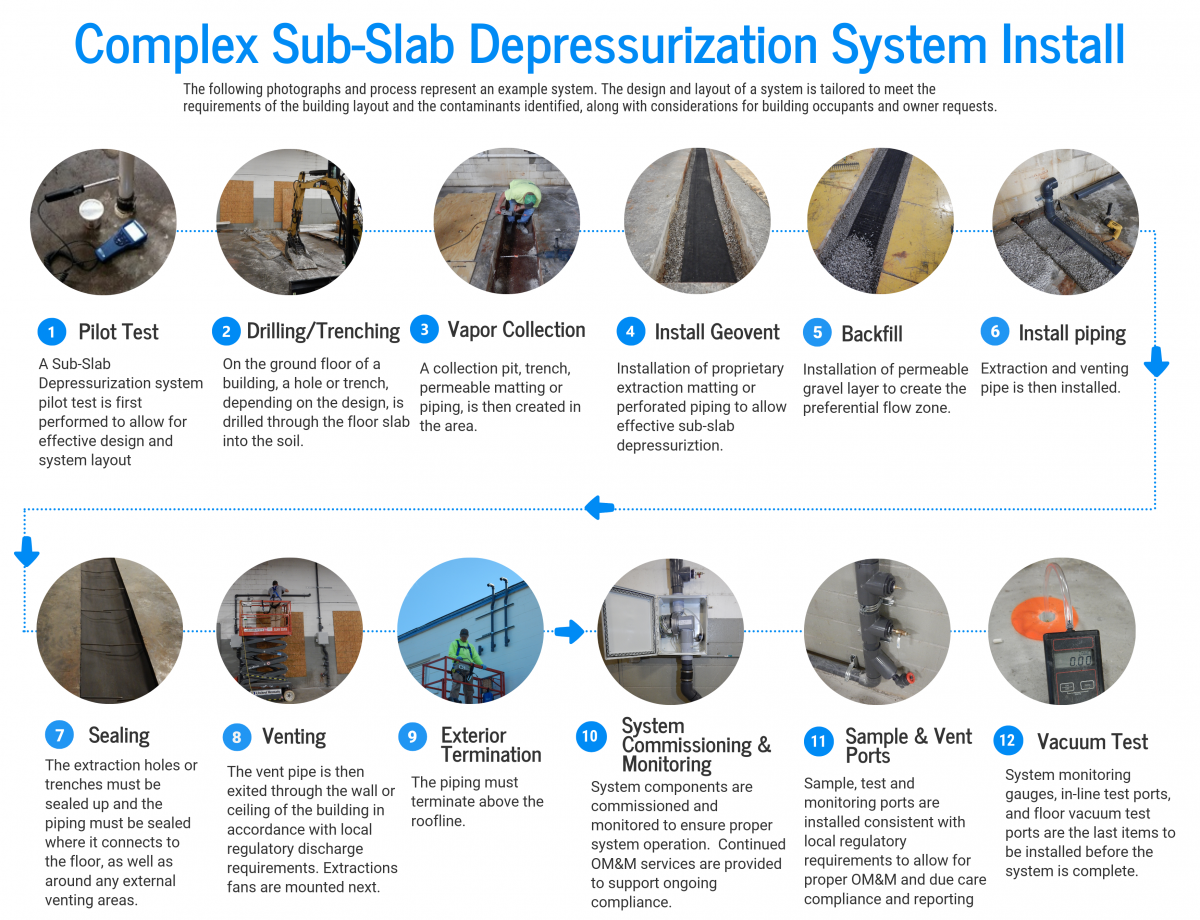

How is a Complex Sub-Slab Depressurization System Installed? {Infographic}

When the potential for vapor intrusion (VI) is identified due to sub-slab vapor concentrations above screening levels, mitigation systems are frequently used to control exposure. For existing structures with potential VI risk, the most common mitigation is the Sub-Slab Depressurization (SSD) technology.

The USEPA defines SSD technology as “a system designed to achieve lower sub-slab air pressure relative to indoor air pressure by use of a fan-powered vent drawing air from beneath the slab.” Thus, even if there are holes, cracks, or other pathways between the building and the subsurface, a well-designed SSD system prevents contaminant vapors from intruding into the inside space.*

Simple SSD systems typically have a consistent and relatively large radius of influence (ROI) as determined from a Pilot Test, can be implemented using individual extraction points, and are applied to smaller footprints in structures with standard slab-on-grade foundations. These structures are usually single-story and do not have significant relic subsurface structures in place below the building which may complicate consistent air flow under the slab.

Complex SSD Systems are those that must overcome one or more of the following site conditions:

• Small and inconsistent ROI as determined by a Pilot Test,

• Require more extensive trench extraction features and multiple extraction fans,

• Must address large footprints and/or multi-story buildings,

• Complex basement/slab-on-grade arrangements,

• Shallow groundwater under the building slab,

• Buildings with significant obstructions to the placement of extraction features, transmission piping or other mitigation equipment, and

• Buildings with potential explosion risk due to VI such as the presence of methane in the subsurface.

Previously, we outlined how PM’s vapor intrusion experts install simple SSD Systems. This time, we look at how complex SSD systems are installed.

*Source: http://www.cpeo.org/techtree/ttdescript/ssvd.htm